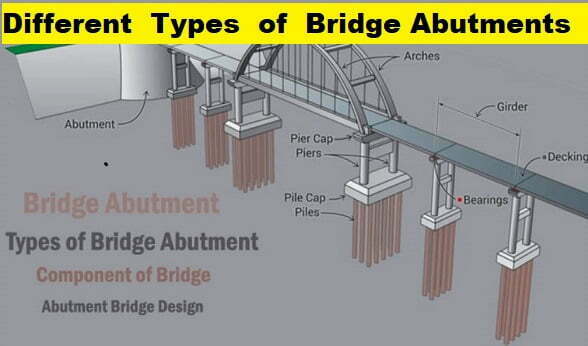

What is Bridge Abutment?

The bridge abutment is important at the bridge’s end because it supports the bridge’s superstructure. It also connects to the road below and supports the bridge via the abutment. The bridge path is supported by the infill material.

The abutment used in the bridge is determined by the location of the site and the function of the need. Abutment is available in a variety of shapes and sizes. The cost and type of abutment used in relation to the site location determine its use.

The Purpose of Bridge Abutment

- It uses the bridge abutment to transfer the load on the bridge and the wind load from its dead weight to the earth.

- The abutment is responsible for transferring load from the superstructure to the foundation components.

- Abutment helps to ensure a safe landing by supporting one edge of the approach slab.

- Abutments in arch bridges provide stability between vertical and horizontal force elements.

Components of Bridge Abutment

Bridge Seat

The bridge deck is held up by a horizontal shelf close to or on an abutment. While those positioned along a span would offer support to reduce long-term stress, these would be used to secure the end of a bridge to an embankment.

Wing Wall

Only the embankment is supported by this portion of the abutment. This helps to maintain the side slope embankment of the bridge. Short retaining walls are used to protect the barrier from erosion as well.

Rear Wall

Back walls are used in bridge abutments to support the embankment. The side walls are constructed vertically at the edge of the bridge in accordance with the slope of the embankment. The extension joints of the bridge deck are supported by the back walls.

Abutment Pile

The filament used to join the foundation of the abutment to the bridge’s seat is known as the abutment pile. The height of the bridge and the depth of the obstruction determine the length of the pile (canal, river, and stream).

Abutment Footing

This part of an abutment connects the vertical, load-bearing portion of the abutment to the ground and is typically buried in the ground. It consists of a horizontal surface that is occasionally wider than the bridge and distributes weight.

Bridge Abutment Types

Gravity Abutment

Such an abutment has a strong foundation. The dead weight of this kind of abutment can withstand both water pressure and earth pressure. The structure of the gravity abutment rests directly on the ground. Due to its weight, it is kept on the ground by the gravitational pull of the earth.

Gravity Abutment in a U-shape

These bridge abutments have wings that are parallel to the face and act as counter-forts. These abutments are very tough. The wing walls of the abutment form a 90° angle with the seat of the bridge. Two piles spaced evenly across the width of the bridges form a U-shaped abutment. Concrete with reinforced cement is used to construct these types of abutments. A foundation connects the bottom of both abutment piles. The foot of both heaps is the same.

Stub Abutment

A relatively short abutment constructed after the embankment is finished is referred to as a stub abutment or a perched abutment. The abutment can be built later if necessary, and the embankment can be compacted without it getting in the way. These abutments are positioned at the top of fill embankments and are as short as possible. Stub abutments typically can only support soils that are slightly thicker than the superstructure’s thickness.

Stub abutments are economical, but they frequently lengthen the end spans. Additional wall abutments are frequently constructed to the full height of the crossing, and they may be noticeably taller than the crossing itself.

Slight Abutment

Between full height and stub-abutment heights is the semi-stub abutment. The full-height abutment is built at the bottom of the embankment, as opposed to stub abutments, which are built at the top. These abutments are built between the top and bottom of the embankments. Because they are longer than full-height abutments and larger than stub abutments, they are referred to as semi-Stub abutments.

Abutments for Cantilever Walls:

A cantilever abutment has two purposes: it keeps soil in place behind the bridge’s ends and supports the superstructure. Some types of wall abutments are referred to as stub abutments. These abutments are built to be as short as possible and are installed at the top of fill embankments. Stub abutments frequently can only support soils that are slightly higher than the thickness of the superstructure.

Stub abutments have a tendency to lengthen the end spans but can be very cost-effective. Other wall abutments can be much taller and are frequently constructed to the full height of the crossing. Full-height abutments have shorter end spans but are more difficult to build

Abutments with Full Height:

This style of the abutment is typical in crowded urban areas where structural depth is necessary. It functions as a low-level roadway abutment built at a high height to support the entire construction.

Abuse of the counterfort

For the counter-fort, the abutment acts as a retaining wall. The wall is joined to the footing in the counter-fort abutment by a thin wall known as the main counter-fort. These counter-fort walls are built at regular intervals.

An abutment that is mechanically stabilized

Abutments of bridges have also been supported by mechanically stabilized walls. The bridge seat and footing are supported directly on the reinforced backfill, as shown schematically in the accompanying image. Concepts for designing mechanically stabilized walls can be used. Abutment loads, especially in the upper part of the backfill where the bridge loads are concentrated, increase the need for reinforcement. This abutment design was infrequently used on the Thionville, France, Moselle River Bridge.

Abutment by Spill-Through

Short and stubby abutments are known as spill-through abutments. This type of abutment is supported by columns or pedestals that extend to the ground. Similar to closed abutments, this type of abutment needs to be constructed before the building is built. To lessen uneven earth pressure and abutment lateral displacement, the fill is applied to both sides of the pedestals at once. On the other hand, it is very challenging to properly compact the fill around the pedestals. If the final slope is not covered with asphalt, riprap, or some other material, it is also prone to erosion.

Pile-Bent Abutment

This kind of abutment is used in place of the support structure that resembles a wall. In essence, it is a series of columns or piles that provide structural support.

Advantages of Abutment Bridges

The following are some benefits of integral bridges over conventional bridges:

- The cost of construction and maintenance is significantly lower than for conventional bridges.

- Abutment bridge construction is quick and easy.

- Because bearings and expansion joints are no longer necessary, there is less tolerance restriction.

- The foundation of the old bridge may be used as the foundation for the integral bridge if it is being built in place of the old bridge. Thus, the project’s cost decreases.

- Using the drainage layer that is provided behind the integral abutments, it is possible to eliminate water leakage on important structural components.

- Since there are no expansion joints, the ride quality of vehicles on integral bridges is smoother and more comfortable.