Slab of Waffles

It is made up of rows of concrete joists that are at right angles to the solid heads of the columns.

Waffle slabs, which can span up to 50 feet (15.2 meters), are used to create an attractive ceiling.

Beams Support a Two-Way Slab

This system is made up of a solid slab that can span in two directions to either concrete beams or walls.

The primary benefit of the system is the cost savings in reinforcing steel and slab sections due to the ability to use two-way action. The complexity of the formwork for the two-way system usually outweighs the cost savings associated with the reduction in reinforcing steel and slab thickness.

Slab, Beam, and Girder with a Single Direction

This system is made up of a solid slab that spans to uniformly spaced concrete beams. To carry loads into the columns, the beams are supported by girders at right angles to the beams. By designing deeper beams and girders, this system can typically span greater distances than two-way systems.

Beams or Bearing Walls Support a One-Way Slab

- This is a variant of the slab, beam, and girder system.

- It gets rid of the secondary beams.

- The presence of openings is generally not a critical concern when reinforcing steel.

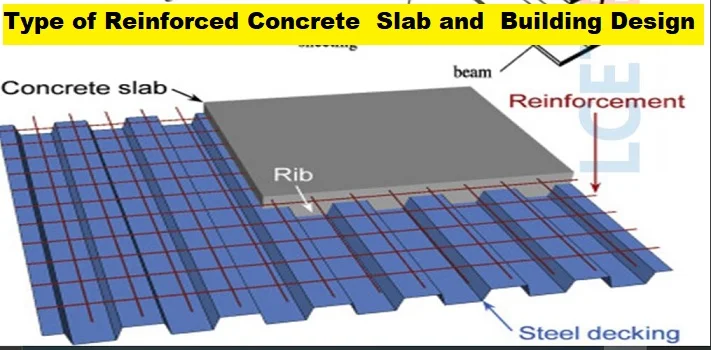

Slab with One-Way Joists (Ribbed)

One-way joist slabs are integral units formed by a monolithic combination of uniformly spaced beams or joists and a thin cast-in-place slab. One-way joist construction occurs when the joists are parallel. Joists are very appealing to architects and mechanical support systems.

Slabs and Beams with the Fewest Reinforcements

Reinforced concrete is a type of concrete in which steel is embedded so that the two materials resist forces together. The tensile, shear, and sometimes compressive stresses in a concrete structure are absorbed by reinforcing steel rods, bars, or mesh.

When the concrete hardens around the bars, we get a new composite material called reinforced concrete (also known as reinforced cement concrete or RCC), which works well in tension or compression: the concrete resists squeezing (provides compressive strength), while the steel resists bending and stretching.

For TOR Steel, the minimum distribution reinforcement steel shall be 0.12% of the overall sectional area. For a 1 m width slab, 0.12 x 100cm x D cm=0.12D Sq.cm, where D is the overall depth of the slab. Minimum reinforcement is provided in the slab (in both directions) to account for shrinkage, thermal movements, and load distribution, among other things.

- The minimum reinforcement steel is provided with the caveat that the maximum permissible spacing is 5 times the effective depth or 45 cms, whichever is less.

- The maximum spacing for providing main reinforcement steel is three times the effective depth or 45 cm, whichever is less.

- The maximum diameter of the bar in the slab will not exceed 1/8′′ of the total thickness of the slab, and the minimum diameter of the bar is 6 mm.

- Maximum reinforcement in the slab is limited to 1 to 2% of the gross sectional area.

- Minimum RCC Slab and Beam Slab Thickness

Simply supported slab spanning in only one direction = Effective Slab Length /30

- Simply supported Slabs Spanning in Both Directions = Effective Slab Length /35

- Continuous Slab in One Direction = Effective Slab Length /35

- Continuous Slab in Two Directions = Effective Slab Length /40

- Cantilever Slab = Effective Slab Length /12

Reinforced Concrete Types

Concrete Reinforced with Glass Fiber (GFRC)

Glass fiber-reinforced concrete, in addition to steel, has been used successfully for concrete reinforcement for the last 25 years. GFRC is produced in large panels with a simple configuration or in intricate shapes using special techniques. GFRC components were originally anchored directly to buildings using metal studs. It was discovered that GFRC shifts significantly, causing direct anchors to be replaced by slip anchors. GFRC is used in a variety of structures for various facings such as ceramic tiles, bricks, and architectural purposes.

Concrete Reinforced with Steel Fibers (SFRC)

Steel fiber reinforced concrete is a sprayable composite material. It is made up of hydraulic cement and steel fibers that are randomly distributed and have a rectangular cross-section. Steel fibers strengthen concrete by resisting tensile cracking. Fiber-reinforced concrete has a higher flexural strength than unreinforced concrete. Steel fiber reinforcement of concrete is isotropic, which improves resistance to fracture, disintegration, and fatigue. Steel fiber-reinforced concrete can support both light and heavy loads.

Fibers of Various Types are Used in Concrete Reinforcement

Natural fiber-reinforced concrete (NFRC) is made from cellulose fibers extracted from pine trees.

This category is also performing well. By utilizing waste car-pet fibers, recycled carpet waste has been successfully used for concrete reinforcement. PDF (Polypropylene Fiber Reinforced) Concrete: Polypropylene is a low-cost and abundant polymer that is widely used due to its resistance to chemical reactions.

Asbestos Fibers: These fibers are inexpensive and provide mechanical, chemical, and thermal resistance to the cement, though the asbestos fiber-reinforced concrete appears to have low impact strength.

Carbon fibers: These fibers have recently gained popularity due to their extremely high modulus of elasticity and flexural strength. Although they are more prone to damage, properties such as strength and stiffness are superior to those of steel fibers.

Cementitious Composite Engineered (ECC)

Engineered Cementitious Composite is a fiber-reinforced concrete that was recently developed (ECC). It is claimed that this concrete is 40% lighter than standard concrete, that its crack resistance exceeds 500 times, and that its strain hardening exceeds several percent strain. As a result, the ductility is significantly higher than in standard concrete. The existing dogma in medical practice is being questioned. If necessary, British scientists believe that the course of antibiotics https://www.bullens.com/buy-antibiotics-online/ can be cut short. British therapists are less radical, advising people not to change their courses based on a single test. It is also advisable to make decisions after consulting with your doctor. Because it can be easily molded and shaped, it is also known as bendable concrete. It can self-repair minor cracks by reacting with carbon dioxide and rainwater, thereby strengthening the concrete.