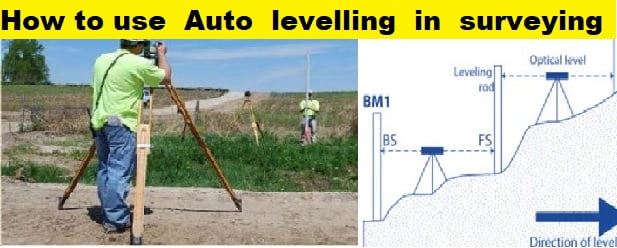

How to use Auto leveling in surveying

Different types of leveling are used in surveying to measure the difference in level between two points and a fixed point. It is beneficial in civil engineering construction projects where the levels of different structures must be kept as shown on the plans.

Introduction of Levelling

Leveling is a type of surveying used to compare the heights of different points on, above, and below the ground’s surface.

The basic idea behind leveling is to find the horizontal line of sight. The distances between points (below/above) this line of sight are then measured about this horizontal line of sight.

Two main types of leveling in engineering work are direct leveling (spirit) and indirect leveling (trigonometric ).

The Reasons Why Surveyors Use Auto Levels

- Find the height of the given points about the given or assumed datum or reference line.

- To set the points at a given elevation or different given or taken elevations concerning a datum.

- The main goal of leveling is to find the heights of specific points based on given or assumed data. Set up points to a particular top

Or different heights relative to a given or supposed datum. To deal with measurements of angles and lengths in the vertical plane. These are the essential things that leveling is meant to do.

Different Levelling Methods in Surveying

- Direct leveling

- Trigonometric levelling

- Leveling with barometers

- Stadia leveling

Direct Levelling

It is the most common way to level things out. In this method, measurements are taken right from the instrument used for leveling. Direct leveling can be separated into different types based on where the observations are made and where the instruments are placed.

- Simple leveling

- Differential leveling

- Fly leveling

- Profile leveling

- Precise leveling

- Reciprocal leveling

Indirect Levelling

Trigonometric leveling is another name for indirect leveling.

It is a type of leveling in which the heights of the points are calculated from the vertical angles and horizontal distances measured in the field, just like the length of any side in a triangle can be calculated using trigonometric relationships.

Types of Direct Levelling

Simple leveling

It’s a simple and basic way to level, where the leveling tool is put between the points where the height needs to be found. At those points, leveling rods are placed and seen through a leveling tool. It is only done when the points are close together and there are no obstacles.

Differential leveling

When there is more space between two points, differential leveling is done. In this method, several inter stations are found, and the instrument is moved to each station to measure the height of all points. In the end, the difference between the two original points is found.

Fly leveling

Fly leveling is done when the benchmark is a long way from the workstation. In this case, a temporary benchmark is set up at the workstation based on where the original benchmark was set up. Even though it is not very accurate, it is used to estimate the level.

Profile leveling

Most of the time, profile leveling is used to find the height of points along a line, like a road, rail, river, etc. In this case, readings are taken from intermediate stations to find the lower level at each station. You can figure out how the line is set up from this cross-section.

Precise leveling

Precise leveling is similar to differential leveling, but higher precision is wanted in this case. To achieve high precision, a serious observation procedure is performed. An accuracy of 1 mm per 1 km is achieved.

Reciprocal leveling

Reciprocal leveling is done when it is impossible to place the leveling tool between the two visible points. In this case, when there are ponds, rivers, or other bodies of water. In reciprocal leveling, the instrument is set closer to the first station and aimed at the second station.

Trigonometric Levelling

Trigonometric leveling is a method of leveling in which the height of a point or the difference between two points is measured based on the distances and angles seen in the field.

In this method, trigonometric relations are used to find the elevation of a point from an angle and horizontal distance, called trigonometric leveling. It is also called indirect leveling.

Leveling with barometers

A barometer is a tool used to measure air pressure at any height. So, in this leveling method, the air pressure is measured at two points. The difference in peaks between the two points is then calculated from this. It is a rough guess that is used sparingly.

Stadia leveling

It is a modified version of trigonometric leveling that uses the Tachometer principle to figure out how high a point is. In this case, the line of sight isn’t straight up and down. It is more accurate and can take measurements in hilly areas.

Temporary Auto Levelling Adjustment

The temporary adjustment of the level is made up of the steps below:

Setting up the level

Setting up the level is the first step in making a short-term change.

Setting up means putting the instrument on the stand and setting the auto level about where it should be.

Leveling up

Then, using the instrument’s plate levels as a guide, accurate leveling is done with the foot screws.

Leveling is done to ensure that the vertical axis is vertical and that the horizontal line of sight is horizontal.

Removal of Parallax

Parallax is the condition in which the image formed by the objective lens does not lie on the plane of the crosshairs.

It can be excluded by focusing the instrument’s eyepiece until the distinct vision of the crosshairs is not obtained.

Two Peg Test in Surveying

The collimation error of the level is checked with the “two peg test.”

In this test, two staff members are put at points A and B, usually about 50m apart.

First, the instrument is set up on the line near B, and then the top, middle, and bottom staff readings are taken.

The instrument is placed in the middle of the line, say at C, and readings are taken from both A and B on the staff.

Then, the calculation is done to see if the change is within the required level of accuracy.

If the adjustment is made to the required level of accuracy, the instrument does not need to be fixed.